Choosing the Right Thermal Imaging Camera: Key Factors to Consider

When it comes to selecting a thermal imaging camera, understanding your specific needs is important. These advanced devices are invaluable in various applications, from industrial inspections to medical diagnostics. Here are the essential factors to consider when choosing the right thermal camera for your requirements.

Temperature range

The first aspect to consider is the temperature range you need to measure. Thermal cameras have specific limits on the highest and lowest temperatures they can detect. Knowing the temperature parameters of your application will help you choose a camera that meets your needs. For instance, if you’re working in environments with temperatures ranging from -50°C to 900°C, an LWIR camera would be appropriate. Conversely, if you need to measure higher temperatures (up to 2450°C), you might consider an NIR-SWIR camera

Detection Range

- Distance: Determine the maximum distance at which the system needs to detect objects or heat sources. For example:

- Short-range: 50–100 meters (e.g., indoor monitoring).

- Long-range: 1–2 kilometers or more (e.g., perimeter security or large outdoor areas).

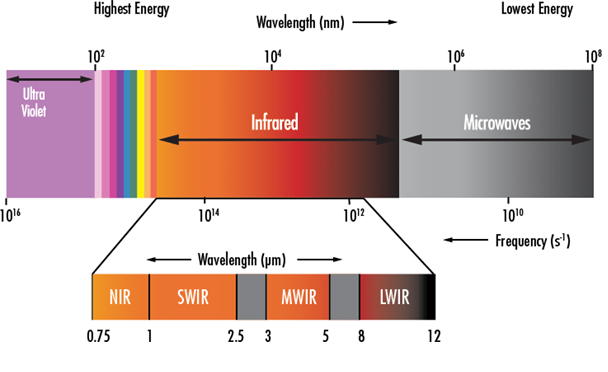

Spectral range

The spectral range refers to the wavelengths that the thermal camera can detect. This factor is essential because it affects measurement accuracy. Emissivity, which indicates how well a surface emits thermal radiation, plays a role here. To achieve precise measurements, opt for a camera with the shortest wavelength that aligns with your temperature range. For example, a 1-micron NIR camera is ideal for measuring temperatures starting from 450°C, while LWIR cameras are suited for broader ranges.

According to the temperature ranges we want to measure; the most used industrial thermal cameras are of the following:

- LWIR for “low” temperature measurements between -50°C and 900°C (exceptionally up to 1500°C)

- NIR-SWIR for hot temperature measurements (450°C to 2450°C)

- MWIR for measuring low and intermediate temperatures with high precision (the vast majority refrigerated and expensive)

Sensitivity (NETD)

The sensitivity of a thermal camera is measured by the Noise Equivalent Temperature Difference (NETD), which indicates the smallest temperature differential the camera can detect without being influenced by its own noise. A lower NETD means(<50mK) finer temperature details. Conventional cameras typically have a NETD of 80mK to 100mK, while high-performance models can achieve 10mK. If you’re measuring large temperature differences, a camera with a lower NETD may not be necessary.

The more sensitive the detector (lower NETD), the finer the temperature details the thermal camera can display.

If the objectives to be measured have large temperature differences, a camera with a low NETD is not necessary.

Resolution

Resolution is a critical factor that determines the quality of the thermal images produced. It refers to the number of pixels in the camera’s detector; higher pixel counts lead to sharper images and more accurate measurements. Common resolutions in the industry include 80×80, 160×120, 382×288, and 640×480 pixels for LWIR cameras. Higher resolutions are particularly beneficial for measuring smaller targets from greater distances.

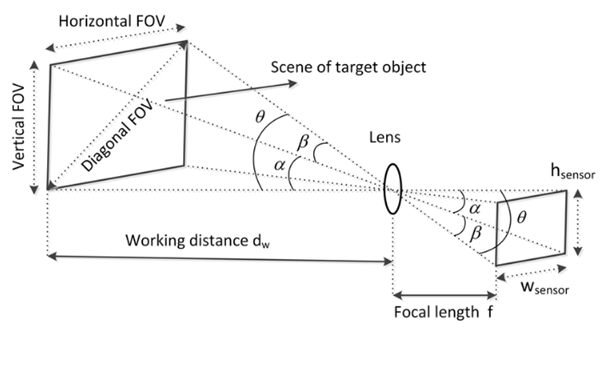

Field of View (FOV)

The field of view (FOV) is determined by the thermal camera lens and refers to the extent of the scene that the camera can capture. The greater the field of view, the greater the area or space that can be captured with the thermal camera.

Some cameras are available with multiple lenses for several types of applications. A camera that allows you to change the lens increases its versatility.

Knowing the distance at which the camera can be installed and the size of the smallest detail that we want to measure in the scene, allow us to identify the ideal optics for our application.

Focus

Accurate focus is paramount for clear thermal images and reliable temperature measurements. There are several focus systems available:

Fixed Focus: Simple but limited to one focal length.

Manual Focus: Allows for precise adjustments.

Autofocus: Automatically adjusts for clarity.

High-performance thermal cameras often feature manual or automatic focus systems for optimal results.

Ambient temperature and environment

Lastly, consider the environmental conditions where the thermal camera will be used. Harsh industrial settings may require additional protective accessories, such as:

Air- or Water-Cooled Housings: For extreme heat environments.

Air Purge Devices: To keep the lens clean in dusty conditions.

Outdoor Housings with Heaters: To prevent freezing in cold climates.

Thermal imaging camera for offshore applications

Choosing a thermal imaging camera for offshore applications requires careful consideration due to the harsh and demanding environments typically encountered, such as oil rigs, wind farms, or marine vessels. Offshore thermal cameras are used for safety monitoring, equipment inspection, leak detection, and fire prevention. Below are the key factors to consider

1. Environmental Durability

- IP Rating: Look for cameras with a high Ingress Protection (IP) rating (e.g., IP67 or IP68) to ensure resistance to water, dust, and salt spray.

- Corrosion Resistance: Offshore environments are highly corrosive, so choose cameras with rugged, corrosion-resistant housings (e.g., stainless steel or marine-grade aluminum).

- Operating Temperature Range: Ensure the camera can operate in extreme temperatures, both high and low, common in offshore environments.

2. Detection Range and Field of View (FOV)

- Detection Range: Offshore applications often require long-range detection (e.g., 1–5 km or more) for monitoring large areas like oil rigs or wind turbines.

- Field of View (FOV): Choose a camera with an appropriate FOV for your needs:

- Wide FOV for monitoring large areas.

- Narrow FOV for detailed inspections of specific equipment or structures.

3. Resolution and Image Quality

- Thermal Sensor Resolution: Higher resolution (e.g., 640×480 or higher) provides clearer images and better detection of small temperature differences, which is critical for identifying leaks or equipment faults.

- Image Clarity: Look for cameras with advanced image processing to reduce noise and enhance clarity in challenging conditions (e.g., fog, rain, or darkness).

4. Temperature Range and Sensitivity

- Temperature Range: Ensure the camera can handle the temperature extremes encountered offshore (e.g., -40°C to 2000°C).

- Thermal Sensitivity (NETD): Lower NETD values (e.g., <50 mK) are better for detecting small temperature differences, which is critical for identifying early-stage issues like gas leaks or overheating equipment.

5. Hazardous Area Compliance

- ATEX/IECEx Certification: If the camera will be used in potentially explosive atmospheres (e.g., oil and gas platforms), ensure it is certified for hazardous areas (ATEX Zone 1 or Zone 2).

- Intrinsically Safe Design: For use in high-risk environments, choose cameras designed to prevent ignition of flammable gases or vapors.

6. Integration with Existing Systems

- Compatibility: Ensure the camera can integrate with your existing monitoring or security systems (e.g., SCADA, VMS, or DCS).

- Communication Protocols: Support for standard protocols like ONVIF, RTSP, or Modbus for seamless integration.

- Network Connectivity: Ethernet, PoE (Power over Ethernet), or wireless connectivity for remote monitoring.

7. Analytics and Alarms

- Temperature Threshold Alarms: Notifications for overheating equipment or fire risks.

- Gas Leak Detection: Some thermal cameras are equipped with specialized analytics to detect gas leaks (e.g., methane or hydrocarbon leaks).

- Motion Detection: Automated alerts for unauthorized access or movement in restricted areas.

8. Power Supply

- Power Options: Choose cameras with low power consumption or PoE for easier installation and reduced operational costs.

- Backup Power: For critical applications, ensure the system has backup power options (e.g., battery or solar).

9. Ease of Installation and Maintenance

- Mounting Options: Wall, pole, or mast mounts for flexible installation on offshore structures.

- Maintenance: Look for systems with self-cleaning lenses or easy access for calibration and servicing, as offshore maintenance can be challenging and costly.

10. Cost and ROI

- Initial Cost: Higher-end systems with advanced features will be more expensive.

- Total Cost of Ownership: Consider installation, maintenance, and operational costs.

- Return on Investment (ROI): Evaluate how the system will improve safety, reduce downtime, or prevent losses (e.g., fire damage or equipment failure).

11. Compliance and Standards

- Industry Standards: Ensure the camera complies with relevant offshore standards (e.g., ATEX, IECEx, or DNV-GL).

- Certifications: Look for certifications like CE, UL, or ISO for quality and safety assurance.

12. Scalability

- Expandability: Choose a system that can be easily expanded with additional cameras or integrated with other monitoring systems.

- Future-Proofing: Consider systems with upgradable firmware or software to adapt to future needs.

13. Vendor Support and Warranty

- Technical Support: Ensure the vendor provides reliable technical support and training, especially for offshore installations.

- Warranty: Look for systems with a comprehensive warranty and service agreements.

Example Use Cases:

- Oil and Gas Platforms:

- Monitor equipment for overheating or mechanical failures.

- Detect gas leaks or fire hazards.

- Ensure worker safety in hazardous areas.

- Wind Farms:

- Inspect wind turbine blades for overheating or damage.

- Monitor substations and electrical equipment.

- Marine Vessels:

- Monitor engine rooms for overheating or fire risks.

- Detect leaks in cargo holds or pipelines.

- Offshore Security:

- Monitor perimeters for unauthorized access or intruders.

- Detect small vessels or objects in low-visibility conditions.

Conclusion

Choosing the right thermal imaging camera involves careful consideration of multiple factors, including temperature range, spectral range, sensitivity, resolution, optics, focus mechanisms, and environmental conditions. By understanding these elements, you can make an informed decision that best suits your application, ensuring accurate and reliable thermal measurements.